Melamine-faced MDF Board is a highly popular material today thanks to its durability and aesthetics. This product is currently manufactured by ACC Panel. We invite you to explore the detailed information about this product line below.

What is Melamine-faced MDF Board?

Melamine-faced MDF is an engineered wood product consisting of two layers: an MDF core and a melamine-coated surface. Depending on your needs, you can choose to have one side or both sides coated. This product is widely used in modern interior construction.

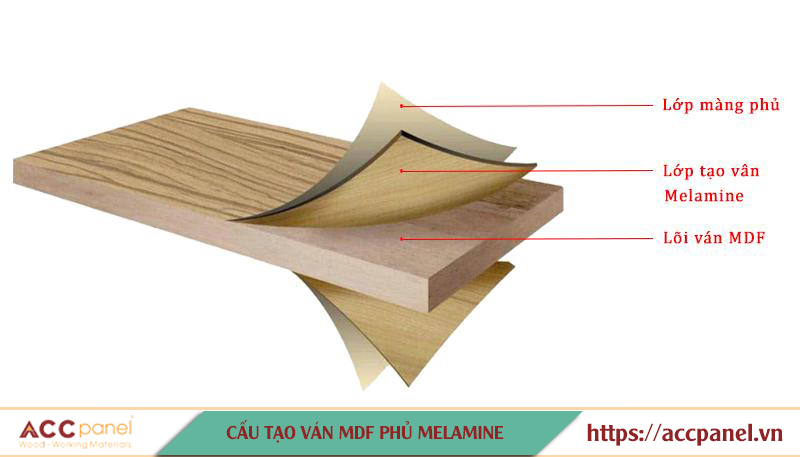

Structure of Melamine-faced MDF Board

The product is composed of three main components:

-

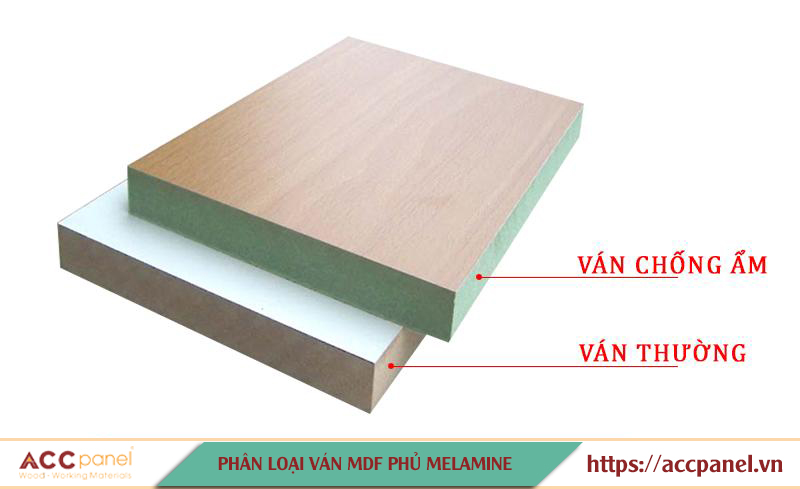

Core Board: The core is made from industrial MDF wood. Depending on requirements, you can choose standard MDF or moisture-resistant MDF (HRM).

-

Melamine Surface Layer: An artificial decorative surface made up of three sub-layers — a base kraft paper layer, a printed decorative paper layer with wood grain patterns, and a protective overlay. Customers can choose to have the board coated on one or both sides as needed.

-

Adhesive Layer: A specialized adhesive that bonds the MDF core with the melamine surface layer.

The combination of these three components creates a melamine-faced MDF board that is visually appealing, high in quality, and highly durable. With a wide variety of surface grain patterns, it offers more options for selecting interior wood products.

Standards for Melamine-faced MDF Boards

| Specification | Details |

| Surface | Melamine (solid color or wood grain as desired) |

| Core | MDF Wood |

| Standard sheet size | 1220 x 2440 (mm) or 1000 x 2000 (mm) |

| Standard thickness | 3mm, 5mm, 6mm, 8mm, 9mm, 12mm, 15mm, 18mm, 21mm, 25mm |

| Tolerance | Not exceeding 0.5 mm |

| Moisture content | 5 – 13% |

| Density | 680 – 750 kg/m3 |

| Adhesive type | UF, MR, E0, E1, E |

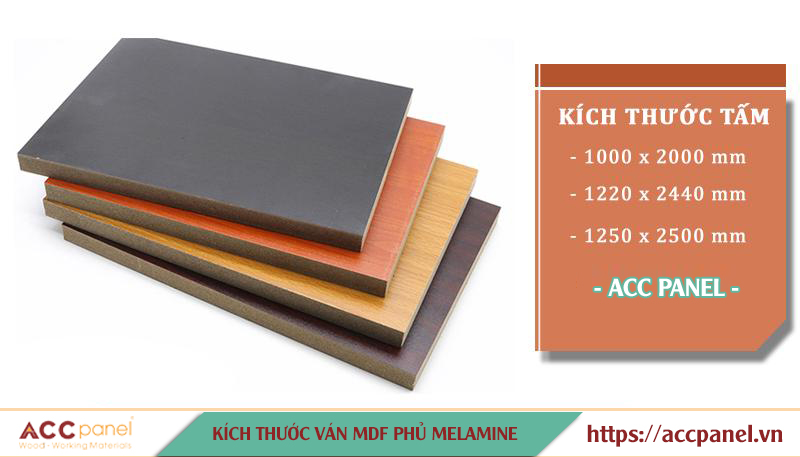

Common Sizes of Melamine-faced MDF Boards

There are three standard sizes most commonly used in the Vietnamese market:

-

1000 x 2000 mm: Standard thickness options include 3mm, 5mm, 7mm, 9mm, 11mm, 13mm, 15mm, 17mm, 19mm, 21mm, 23mm, 25mm, 27mm, 29mm… up to 80mm.

-

1220 x 2440 mm: Thickness options include 4mm, 6mm, 8mm, 10mm, 12mm, 14mm, 16mm.

-

1250 x 2500 mm: Standard thickness options include 18mm, 20mm, 22mm, 24mm, 26mm, 28mm… up to 82mm. This size is a specialized format primarily used for export purposes.

In addition, if customers require custom sizes in large quantities, ACC Panel can fully meet the demand. Please contact our hotline at 0905 964 048 for detailed consultation.

Classification of Melamine-faced MDF Boards

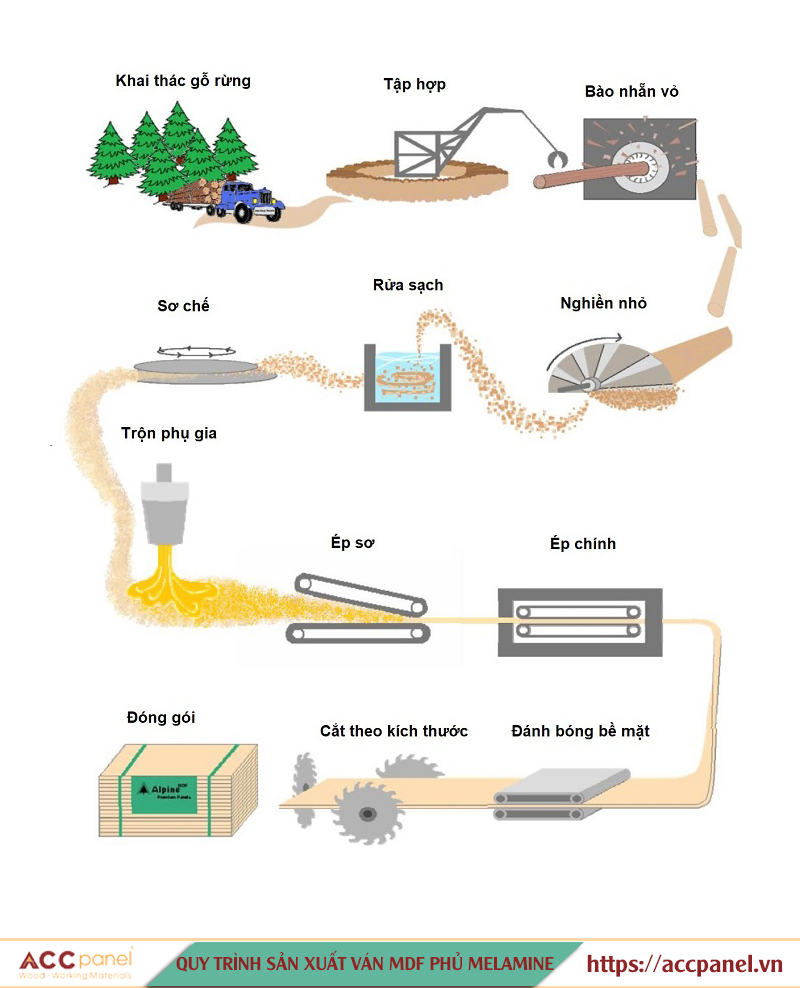

Melamine-faced MDF Board Production Process

-

Harvesting raw timber: Sourcing from eucalyptus, acacia, rubberwood, and other suitable trees.

-

Chipping: Breaking down the raw logs into wood chips of standard sizes.

-

Drying: Drying the wood chips at a controlled temperature.

-

Screening: Sorting the chips to separate different sizes.

-

Mixing with adhesive: Combining the wood chips with industrial adhesive.

-

Forming: Shaping the mixture to meet standard specifications for size, thickness, and density.

-

Pre-pressing & cutting: Light pressing to stabilize the form, then cutting into standard-sized sheets.

-

Hot pressing: Pressing the boards in a high-frequency press under high temperature and pressure.

-

Sanding: Smoothing and refining the surface to ensure quality.

-

Melamine lamination: Applying the melamine surface layer.

-

Quality inspection & packaging: Checking the finished boards for quality compliance before shipment.

Quy trình sản xuất gỗ MDF phủ melamine

Advantages and Disadvantages of Melamine-faced MDF Boards

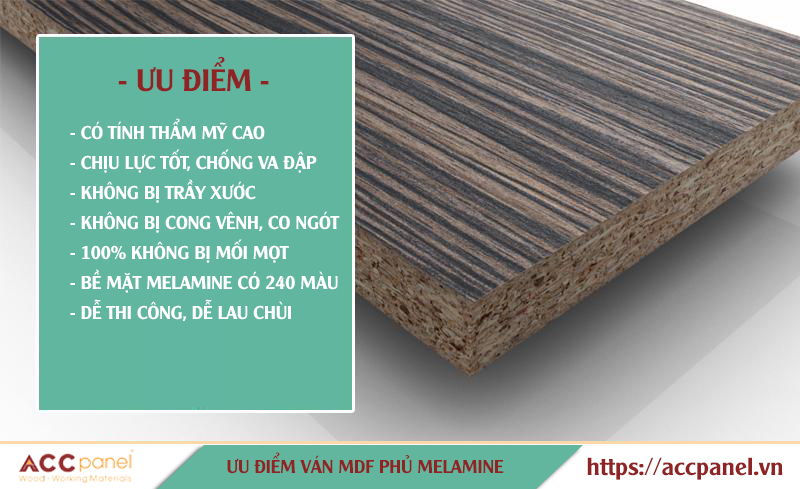

Advantages:

-

High aesthetic value, suitable for modern projects.

-

Good load-bearing capacity and impact resistance.

-

Excellent sound and heat insulation properties.

-

Scratch-resistant surface.

-

Moderate fire resistance.

-

Does not warp, shrink, or crack during use like natural wood.

-

100% termite-proof throughout its lifespan.

-

Melamine surface available in up to 240 color options for customers to choose from.

-

Easy to work with, enabling quick installation.

-

Easy to clean and maintain.

-

Significantly lower cost compared to natural wood.

-

100% free from harmful substances, completely safe and environmentally friendly.

Disadvantages:

-

Good moisture resistance when using HMR core; however, it is not waterproof. Prolonged exposure to water can cause the boards to swell or delaminate.

-

Limited flexibility, making it unsuitable for intricate or highly detailed carving.

-

Fixed size and thickness options, which can be a limitation for certain projects.

-

Painted or decorative surfaces may fade or peel over time.

-

Thickness is limited, so creating furniture that requires greater thickness may involve joining multiple boards together.