Engineered board is one of the most popular materials in interior design thanks to its affordability, aesthetics, and ease of fabrication. However, choosing the right board requires careful consideration of several quality criteria. Let’s explore with ACC Panel what engineered boards are and how to evaluate them.

What is Engineered Boards?

Engineered board is a man-made material produced from natural wood that is ground into fibers or particles, combined with specialized adhesives and additives, then pressed under high temperature and pressure into sheets.

Today, engineered boards are widely used in furniture manufacturing, construction, partition systems, kitchen cabinets, flooring, and many other applications thanks to their versatility and cost-effectiveness.

Common types of engineered boards include:

- MDF (Medium Density Fiberboard)

- HDF (High Density Fiberboard)

- MFC (Melamine Faced Chipboard)

- Particle Board (chipboard)

- Plywood (multi-layer board)

Each type has its own properties and applications, suitable for different interior needs.

Advantages of Engineered Boards

The increasing popularity of engineered boards comes from key benefits such as:

- More affordable than natural solid wood.

- Easy to fabricate, install, and shape.

- Wide range of designs, colors, and finishes (Melamine, Laminate, Veneer).

- Resistance to termites and warping.

- Dimensional stability, less shrinking or swelling with climate changes.

7 Key Criteria for Evaluating Engineered Board Quality

To ensure furniture durability and consumer safety, ACC Panel recommends evaluating engineered boards based on the following criteria:

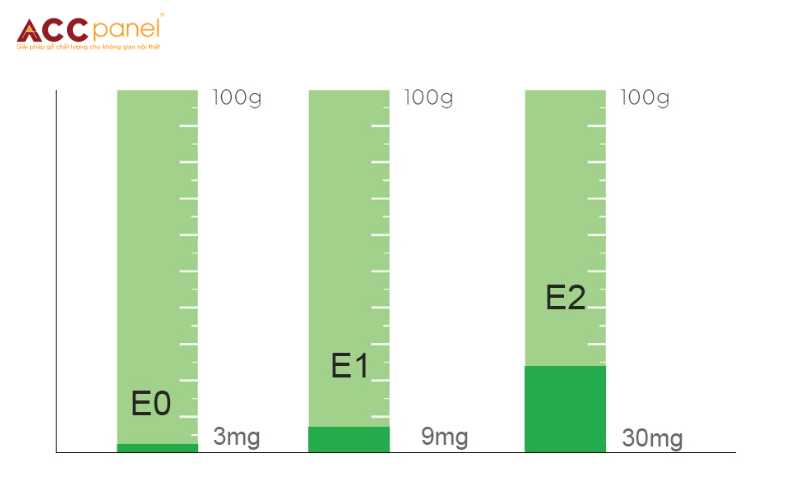

Standard 1: Formaldehyde Emission Levels

One of the most important quality indicators, directly impacting health. Emission levels are classified as E0, E1, E2… ACC Panel Plywood meets E0 standard, ensuring absolute safety.

Standard 2: Density

The density of engineered wood panels is the mass per unit volume of the panel. The common unit used to measure panel density is kg/m³. The density of engineered wood panels typically ranges from 550 kg/m³ to 800 kg/m³, depending on the type of panel and raw materials used in production.

The density of engineered wood panels is usually measured and evaluated according to national and international standards. Below are some commonly used standards for measuring the density of engineered wood panels:

- ASTM D1037 – Standard by the American Society for Testing and Materials (ASTM) for engineered wood panels, including density requirements.

- EN 323 – European Standard for measuring the density of wood-based panels.

- ISO 16978 – International Standard for engineered wood – Method for determining density.

- CSA O325 – Canadian Standard for engineered wood panels, including requirements for density and other properties.

- JIS A 5908 – Japanese Industrial Standard for measuring the density of engineered wood panels.

In Vietnam, engineered wood panels are commonly evaluated according to the EN 323 method. Higher panel density indicates greater fiber compactness, which improves load-bearing capacity and moisture resistance.

Standard 3: Bending Strength (MOR)

Bending strength is measured using the three-point bending test, in which a wood panel sample is bent until fracture occurs, and the force required to break the panel is recorded. The test result is usually reported as the static bending moment needed to break the panel (measuring the force required to bend and break a wood panel sample).

To measure the bending strength of wood panels or other materials, various specific testing standards are applied in industry and research.

In Vietnam, bending strength is commonly determined according to the EN 320 method, measured in Newtons. This index indicates the panel’s ability to withstand bending without breaking. The higher the bending strength, the greater the panel’s load-bearing capacity and durability.

Standard 4: Modulus of Elasticity in Static Bending

This measures the ability of the panel to recover its original shape after being bent, expressed in Newtons. A higher modulus of elasticity improves stiffness and resistance to deformation.

Standard 5: Screw Holding Capacity

This measures the ability of engineered wood panels to hold screws when used in applications where screws are fastened. A higher screw holding capacity increases structural strength and improves fastening performance.

In the engineered wood industry, several international standards are used to evaluate screw holding strength. Below are some commonly applied standards:

- EN 320: European standard for determining the screw-holding strength of particleboard and fiberboard.

- ISO 7890-1: Provides guidelines for measuring screw-holding capacity in particleboard and fiberboard.

These standards specify test methods and procedures to ensure accuracy and consistency in evaluating screw holding capacity in engineered wood production.

Standard 6: Thickness Swelling

This standard determines the swelling in thickness of a panel after immersion in water, applicable to flat or curved boards, including oriented strand board (OSB) and plywood. Thickness swelling is measured by recording the sample’s thickness before and after complete water immersion.

Lower thickness swelling reduces the risk of blistering and damage when exposed to water or high humidity.

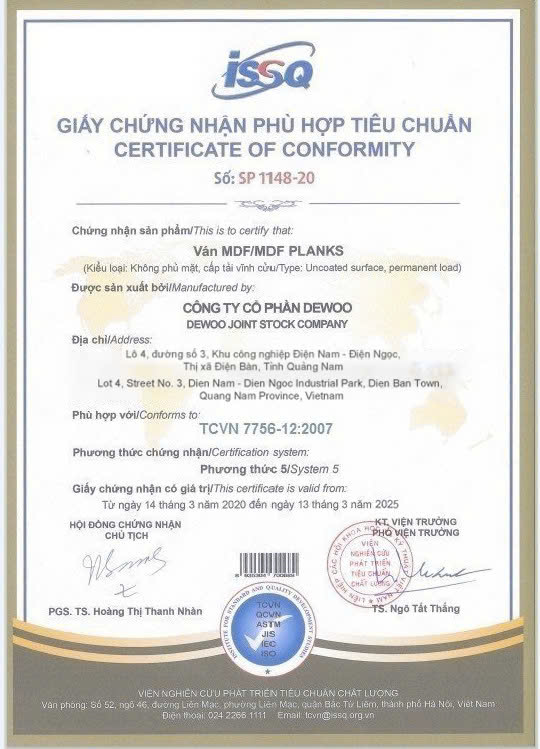

Standard 7: Quality Certification

Engineered wood panels must undergo strict quality control according to standards such as ISO 9001:2015, ISO 3129, and must have clear CO and CQ certificates.

Using certified panels ensures durability and aesthetics for your interior space.

Where to Buy High-Quality Engineered Wood Panels for Furniture?

In Vietnam, many manufacturers produce engineered wood panels, each with their own strengths. Customers can select suppliers based on intended use, budget, and location.

You can purchase directly from Dewoo Joint Stock Company – ACC Panel, a pioneering brand of engineered wood panels in Central Vietnam and the Central Highlands. ACC Panel is committed to delivering the best product quality.

Currently, ACC Panel has warehouses and distribution agents across most provinces in Central Vietnam, the Central Highlands, and Southern Vietnam, ensuring the fastest delivery time to customers.

For free samples, consultation, quotations, and orders, please contact ACC Panel:

Hotline: 1900 252 248 – 0905 964 048

ACC Panel – Quality Solutions for Interior Spaces